Mission

1. PhD objective

The PhD objective is to derive a method for predicting the lifetime of a structural metallic part produced by L-PBF additive manufacturing, thus presenting unavoidable defects. Indeed, it is worth noting that the strength and fatigue life of these components are highly dependent on the presence of these intrinsic defects and mainly their type, size, shape and location.

The key innovations lie in:

- Assessing the influence and criticality of defects on fatigue life using an innovative non-destructive testing (NDT) technique/methodology

- Propose a two-scale approach to establish the link between a local model and a large-scale model:

o The local model detailing defects and enabling simulation of the fatigue damage process (may require simplification of the load case)

o The large-scale model enabling the sizing of a healthy part within an assembled structure subjected to complex mechanical environments (sine/random vibration...)

The PhD should lead to:

- A state-of-the-art mainly focused on:

1) non-destructive testing (NDT) technics,

2) the fatigue life prediction methods published for AM and non-AM parts and,

3) the required experimental data

- The numerical development and implementation in a prototype code a/o commercial FE software (such as Abaqus or others)

- The validation against actual experimental data

- The scientific dissemination

2. Background Context

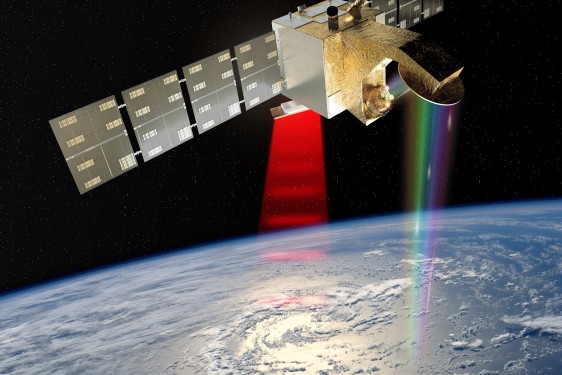

Laser Powder Bed Fusion (L-PBF) is a metal AM technology that has found some applications in the aerospace industry, where most structural components are subjected to cyclic loading throughout their service life, particularly sinusoidal and random vibrations.

Many research projects have been carried out in order to reduce surface roughness, by chemical/electrochemical process, or mechanical processes, e.g. sand-blasting, micro shot-peening or polishing.

In terms of internal porosity effects, the primary method to drastically reduce or even eliminate this porosity consists in applying a post Hot Isostatic Pressing (HIP) treatment, enhancing the High Cycle Fatigue (HCF) resistance of the AM parts.

Nevertheless, all these processes are costly, thereby losing the beneficial effects of producing complex shapes with AM. As final evidence, end users have to live with these intrinsic defects in their AM parts.

Thus, it is clear that a new method for assessing the life cycle of defects needs to be investigated, based primarily on a numerical approach, which will be validated by experimental tests.

3. Methodology and approach

The S-N Wöhler curve is the traditional way of investigation to determine the fatigue life of metallic parts. Nevertheless, as a first disadvantage, it needs a huge amount of time and resources to be plotted. Moreover, it hardly considers the presence of defects, neither their location, shape and size.

To overcome these problems and thus achieve the PhD objective, the proposed methodology will be split in the following steps:

• Manufacturing by L-PBF process of fatigue test samples containing controlled defects (i.e. location, size and shape)

• Grinding the surface of some samples to reduce surface roughness effects and focus mainly on internal defects

• Analysing by NDT techniques the manufactured samples to map and characterise each defect in terms of location, size, shape, potential orientation and quantify its criticality (stress concentration factor). Find a technique for quantifying and identifying the criticality of one defect relative to another.

• Meshing of a full 3D FE model including the actual characteristics of the defect(s) for all the manufactured samples

• FE modelling of each defective sample fatigue stress to plot the Wöhler S-N curve. Life prediction needs to be performed by applying different crack growth options

• Fatigue testing of defective samples, as-built and surface-machined, to validate the previous FEM results

• Develop a simplified model to predict the fatigue life enriched by specific behaviour laws that take into account defect characteristics and provide the best possible description of experimental data

• Experimentally validating this simplified model through additional fatigue tests

• Verifying the model accuracy when applied to a real structural component

4. Why is it a scientific research topic?

This doctoral research could help in guiding the research process by:

- Proposing a specific approach that could be used by scientists and engineers

- Offering a simplified model to assess the fatigue life of both metallic defected samples and structural parts

- Taking into account the defect characteristics deeply studied by numerical simulation and experimental validation

5. Facilities and materials to be used

- Alloys: AlSi10Mg a/o Ti6Al4V

- L-PBF printer

- Mechanical testing: static, fatigue, crack growth, toughness

- Materials characterisation: optical and electronic (SEM) microscopes, roughness tester

- NDT technique: X-ray computed tomography

Hosting laboratories : ICA and ICAM

=================

For more Information about the topics and the co-financial partner (found by the lab!); contact Directeur de thèse - redouane.zitoune@iut-tlse3.fr

Then, prepare a resume, a recent transcript and a reference letter from your M2 supervisor/ engineering school director and you will be ready to apply online before March 13th, 2026 Midnight Paris time!

Profil

Laboratoire

Message from PhD team

CNES will inform about the status of your application in mid-June. More details on CNES website : https://cnes.fr/en/web/CNES-en/10685-st-doctoral-grants.php